Cutting-edge circuitry has numerous applications in multiple fields including medicine, homeland security

Flexible electronics, with applications from consumer to military, have the potential to improve the quality of life and safety for all people.

Flexible electronics specifically refer to electronic circuits that are mounted or built on a pliable substrate, or base material. The substrate can be a variety of inorganic or organic materials, like plastic.

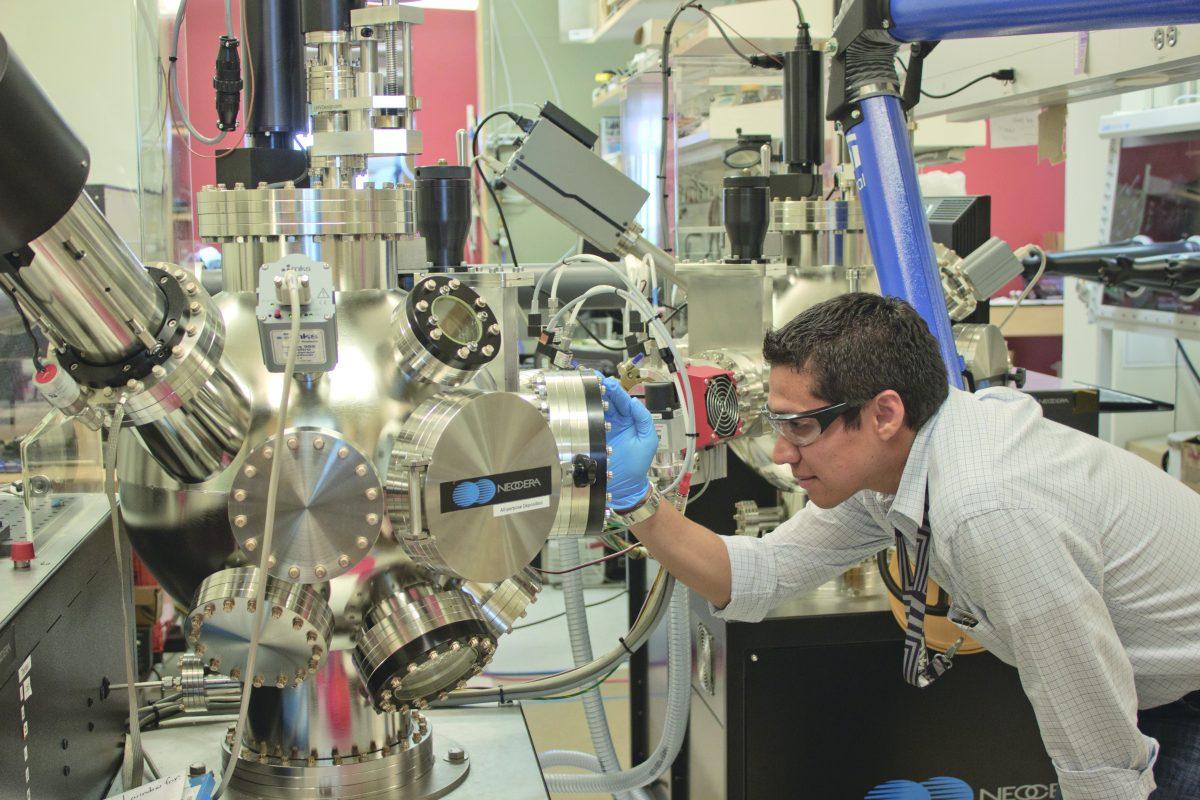

These innovative electronics are gaining headway due to pioneering research by Bruce Gnade, professor of material science and engineering, and Manuel Quevedo, associate professor of material science and engineering.

The ruggedness of flexible electronics is a key advantage over conventional rigid implementations, Gnade said.

“I may want (the flexible circuits) to be conformal. I may want to wrap it around a post … or a balloon, so that the fact that I can do that opens up a lot of applications that you can’t do just with rigid glass,” Gnade said.

“Our biggest effort (at UTD) right now, in flexible electronics, is for radiation sensors,” Gnade said. “We want to make big radiation sensors … that are going to be used out in the field. If you can roll it into a tube, that’s a lot easier to transport.”

In the United States, only a small percentage of cargo is scanned for radioactive materials, Quevedo said. A hand-held Geiger counter is typically used to manually inspect cargo, leading to a time-consuming inspection process that results in most cargo passing into the United States uninspected.

This poses a security issue because dirty bombs could reach the United States undetected, killing civilians and rendering affected regions uninhabitable due to radiation.

To alleviate this risk, Quevedo and his team are working on large area sensors to efficiently scan cargo.

“What we’re developing is a dome — we call it the tunnel of truth — where the cargo can pass through and if there is any radioactivity (emitted neutrons), those neutrons will be sensed,” Quevedo said. “The advantage of flexible electronics is that they are cheap. For us to build this dome, it won’t be a matter of how much it costs.”

Quevedo’s team has developed a small scale prototype to validate the concept. The mockup consists of a radiation source affixed to a toy car and a miniature tunnel of truth that has Quevedo’s radiation sensors embedded within.

As the toy car pass through the tunnel, the prototype transmits a count of the radiation detection events to a smartphone.

However, the processing and fabrication of flexible electronics have been major research challenges in their work, due to the significant variation in the performance of the devices, Gnade said. Overcoming this issue is a key hurdle in enabling circuits to be implemented.

Gnade is investigating new fabrication techniques and circuit topologies that can reduce or tolerate the effects of process variation.

Conventional semiconductor processing benefits from high temperature annealing, which enables imperfections in the fabrication to be cleaned up, Gnade said. For example, if the copper contact resistance is too high, the semiconductor can be annealed in hydrogen to correct the resistance. However, a plastic substrate cannot tolerate high temperature annealing needed for circuits.

Conventionally, this has been acceptable for the flat-panel display industry, which does not require tight control over process variations, Gnade said.

Nonetheless, flat-panel displays have been a reason for the progress of flexible electronics.

“I don’t think flexible electronics would go anywhere if the flat-panel display industry weren’t already there,” Gnade said. “We don’t have to build any of the tools. No one would go out and spend $1 billion to build a factory hoping somebody would buy flexible electronics, but all of those factories are already there.”

Gnade and Quevedo also see many other potential areas to which their technology can be applied.

A curved X-ray detector for CAT scans – enabled by flexible electronics – would allow for easier image reconstruction, Gnade said. The net result of a curved detector is that radiation dosages can be significantly reduced for patients undergoing scans.

In comparison with the conventional approach, which uses a series of flat detectors and continuous radiation, a curved detector would enable a single shot of radiation and easy imaging, Gnade said.

Furthermore, this technology also can facilitate more precise and lower dosage radiation treatment for cancer.

“I had a friend who had a brain tumor, and he had to go through radiation theory,” Quevedo said. “(The doctors) have a beam of radiation … and they basically direct that beam through the head. The problem is that the doctors don’t know where the beam is going — they kind of guess.”

To overcome this challenge, flexible electronics can be used to create a mask for the patient’s head that directs radiation down a pathway to a precise location, with control over the dosage, Quevedo said.

The potential applications extend beyond industrial medical devices to consumer products as well.

“Wearable electronics will have many applications,” Quevedo said. “Right now, you can buy an app that tracks heart rate, but if you can embed (the sensor) in your clothing, that would be great.”

Flexible electronics also can be used to achieve large area electronics. For example, a pliable mat of sensors could be used to cover the floors of a house, which could detect if an elderly occupant falls, Quevedo said.

Other recent mainstream demonstrations include bendable electronic displays showcased by Samsung at last year’s Consumer Electronics Show and LG’s G Flex smartphone.

An example of commercialization of this technology is the flexible display being used by the UTD startup company, Rollout, Gnade said.

Rollout, which is developing a full-size electronic blueprint system, was founded last July by graduate students Alejandro Jacobo and Matthew Hinson, both majoring in innovation and entrepreneurship.

For students interested in pursuing research in flexible electronics, there are many disciplines from which to approach the topic. Quevedo’s multidisciplinary team, for example, consists of electrical engineers, chemical engineers and physicists, to name a few.