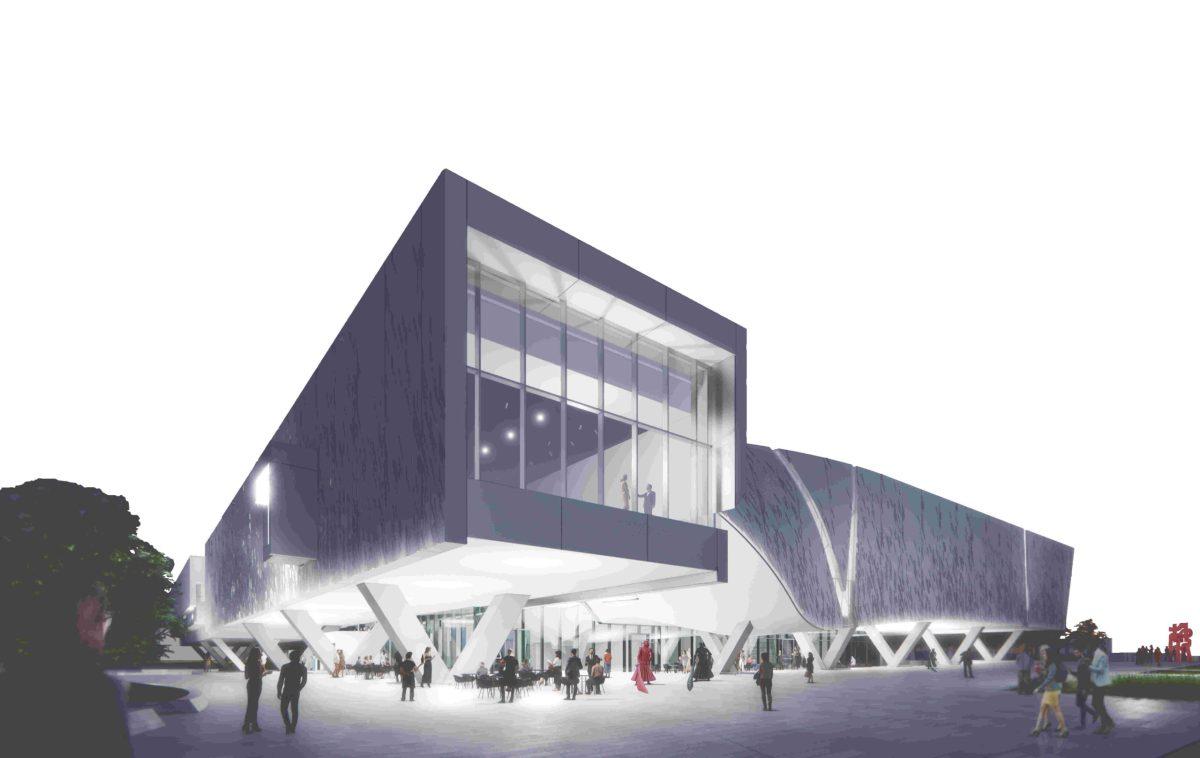

Rendering of the museum near the roundabout. Courtesy of Morphosis Architects.

Morphosis Architects — the firm that created the design for the Perot museum in downtown Dallas — designed the first phase of the Athenaeum, which houses part of the Crow Museum of Asian Art at UTD.

The 56,407-square foot museum is currently under construction south of JSOM. Design partner at Morphosis Arne Emerson said that the team started the project in October 2020 and finished its design in November 2022. General contractors The Beck Group, who are coordinating the construction, estimate it will be completed in April 2024. According to Emerson, the two-story museum will provide a place for students to experience art, socialize with each other and attend events.

“A lot of the ground floor is lifted up, so you can actually walk underneath the building, and so there’s some great spaces under there that can be used all times of the year, at night, during the day, on weekends, for sculptures and events and gatherings,” Emerson said. “We designed this for that very reason: to make sure that it can actually be used as a place for students, faculty and as a teaching building.”

The museum’s lower body is made of concrete, while its upper body is made of steel. Emerson said that he and his team integrated patterns and rhythms from Asian art into the museum’s facade, which consists of 160 precast concrete panels fabricated by Gate Precast, a manufacturer in Hillsboro.

“This precast concrete skin looks very complex, but actually what happens here is that there’s only just a few patterns that we keep repeating everywhere,” Emerson said. “But you can never see that because we’ve turned it into more of a composition, and we’ve got some pretty sophisticated software. This was one of the things that was the most expensive, and by working with the precast contractor … they needed to have repeatable things that they could pour over and over again. That’s something where we effectively were able to save a lot of money and a lot of time by being much more optimized and smart about how we designed everything.”

The Athenaeum’s white color, created with cement and marble chips, was chosen to complement the campus color scheme while still allowing the museum to maintain a unique identity. Feldspar and silica on the surface add sparkle to the building under sunlight.

“Oftentimes museums, especially fine art museums, don’t want to have any natural light whatsoever because of the sensitivities of the work,” Emerson said. “But what was a really incredible opportunity with the collection the Crow Museum had is that a lot of those objects can be in natural light, and that’s very unique. So we tried to really use that as an opportunity to create a connection between what’s happening inside the building, especially the galleries. and then outside of where the new master plan and the arts plaza would be.”

Emerson said the team sourced construction materials from Texas to reduce the project’s global footprint and promote sustainability. In addition, the structure minimizes energy consumption with the insulating properties of precast concrete as well as high-performance glass. Although the team faced challenges in finishing the design, Emerson said that they were able to work well with the contractors and UTD, making quick decisions and reducing costs.

“One of the strengths that our team had was that we had already built a building together, so we know how to effectively get things done in a more optimized and efficient manner,” Emerson said. “Now that we’re in construction, we have a local architect [firm] GFF — Good, Fulton & Farrell — and they go out and visit the site once or twice a week … It’s a very integrated team not only in design, but then also in construction that really allows us to get a building this complex built in a short amount of time with the quality that everyone expects.”

Emerson said he admires UTD leadership’s effort to provide art spaces for students. He added that his team designed the museum with students and faculty in mind and therefore added areas that encourage activity and community building outside the classroom.

“The entire master plan, the collection of four buildings with the big plaza that’s in the middle and all of these overhang spaces, all these exterior spaces [are] for students to hang out [and] for students to meet,” Emerson said. “Students see that the greatest impact we have is that a lot of these spaces that we design are specifically for connecting people … [and it] is what I’m most excited about.”

_____________________________________________________________________________________

Statistics:

Precast concrete facade stats

- 160 Architectural precast panels

- Heaviest precast panel: ~30,000 lbs

Building Size

- Square Footage of the building: 56,407 sf with ~19,000 sf of Gallery and Exhibit space

Building structure stats

- 480 tons structural steel

- 4,203 cubic yards of concrete placed

- 381 tons of concrete reinforcement (rebar) installed

Miscellaneous stats

- Freight Elevator Capacity: 16,000 lbs

- Linear Footage of Distribution and Branch Electrical Wire: ~286,000 lf = ~54 miles of wire

- 113,536 man hours worked – As of 8/28/2023

Construction Schedule

- Demolition Start Date: 9/13/2022

- Substantial Completion Date: 4/14/2024

- Total Work Days (Excluding Weekends and Holidays): 393