Researchers at UTD are looking to nature to advance sensory technology through electronic whiskers.

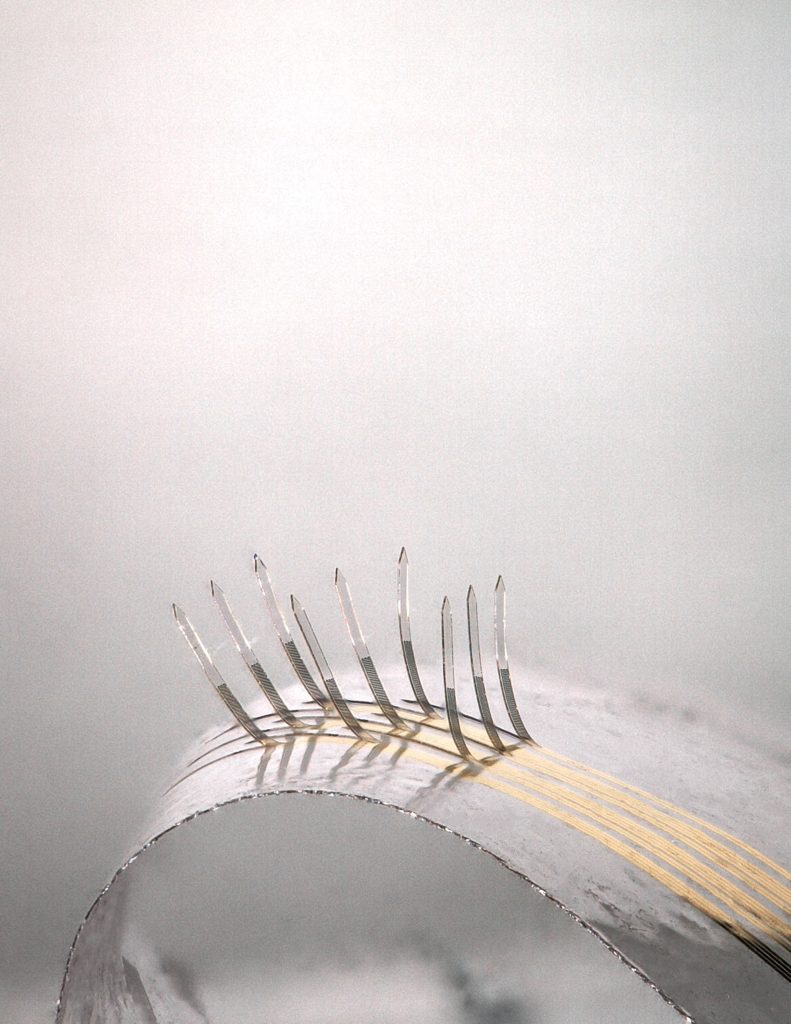

UTD alumnus Jonathan Reeder began working on the project in 2013 while completing his doctorate in materials science and engineering. The sensors, which resemble whiskers, are made of shape-memory polymers and change shape in response to heat. Reeder said this response allows the sensors to adopt a 3D form and capture more stimuli, which could advance robotic and prosthetic technology.

“The basic function of the electronic whisker is to interrogate the surrounding that a robot or a prosthetic might be in and to obtain all types of information,” Reeder said. “That could be temperature, surface roughness, material stiffness and surface texture in order to give a computer… a rich understanding of the surrounding environment.”

Reeder said the innovation lies in defining the size of the whiskers as well as using heat to give them 3D properties. The initial goal of the project was to make brain probes that rely on neural sensors. The challenge was figuring out how to make the sensors move in 3D space.

“We tried a number of different avenues for moving in three-dimensional space,” Reeder said. “We tried magnetic materials, manual assembly, electrostatics, so using warm air to assemble was something that came along toward the end.”

3D electronic assembly is an emerging field in materials science. Reeder said the inspiration for this project came from reading papers by leaders in the field, and after switching the practical application of the sensors from neural interfaces to robotics and prosthetics, researchers now face another obstacle. The technological data gathered from sensors must be translated into biological data and understood by human prosthetics.

“I’m focused on the materials science side, which is developing the sensors which will have some quantifiable electrical response to a (stimulus). What happens with that data is a whole other field,” Reeder said. “You would use processing algorithms to filter the data, so that would be future work, and hopefully with other collaborators we can extend into that area.”

Reeder’s McDermott fellowship gave him the independence and funding to start the project and materials science and engineering professor Walter Voit served as Reeder’s doctoral advisor and provided guidance throughout the process.

Bioengineering senior Sarah Rains got involved with the project in February 2016 through Voit’s recruitment efforts, which involved sharing information about the project during one of her classes. Rains said the project helped her gain new skills as a freshman such as handling Class 4 lasers, which were used to cut the polymer.

“I had a really good mentor – Jonathan was so nice and helpful and everyone I encountered at the lab was helpful,” Rains said. “I was able to bounce ideas off of the other authors and they helped me to get my feet wet into research and also grow as a young researcher.”

As for the future, Reeder said he hopes to see real-world applications of these sensors in prosthetic devices to provide a positive change in the lives of the general public.

“Right now, it’s a new type of sensor and it works on a bench top, but can we ever take that from the bench top and make it to the real world and have a tangible impact on someone’s life?” Reeder said. “I think that would be the best goal that we can imagine.”

Leave a Reply